Engineers with a combined 100+ years in design, construction, commissioning, and operations.

11 years of research and development

97 patent filings – 11 core inventions

Rid the world of reckless use of resources.

Rid the world of mounting waste.

Rid the world of growing liabilities for future generations.

Watch how plasma’s converted waste continues the product life cycle by regenerating products and materials which traditionally would have reached the end of their service life. This stage is a key aspect of the process allowing for the transition from the traditional linear economy to the circular economy.

Our company is fully committed to offering the solutions needed to help our customers meet their sustainability and ESG goals. Whether that includes waste remediation coupled with reliable renewable baseload power or low energy produced green hydrogen, our approach allows us to work towards achieving a cleaner and healthier environment for everyone.

Solutions

Development

Solutions

Engineering

Support

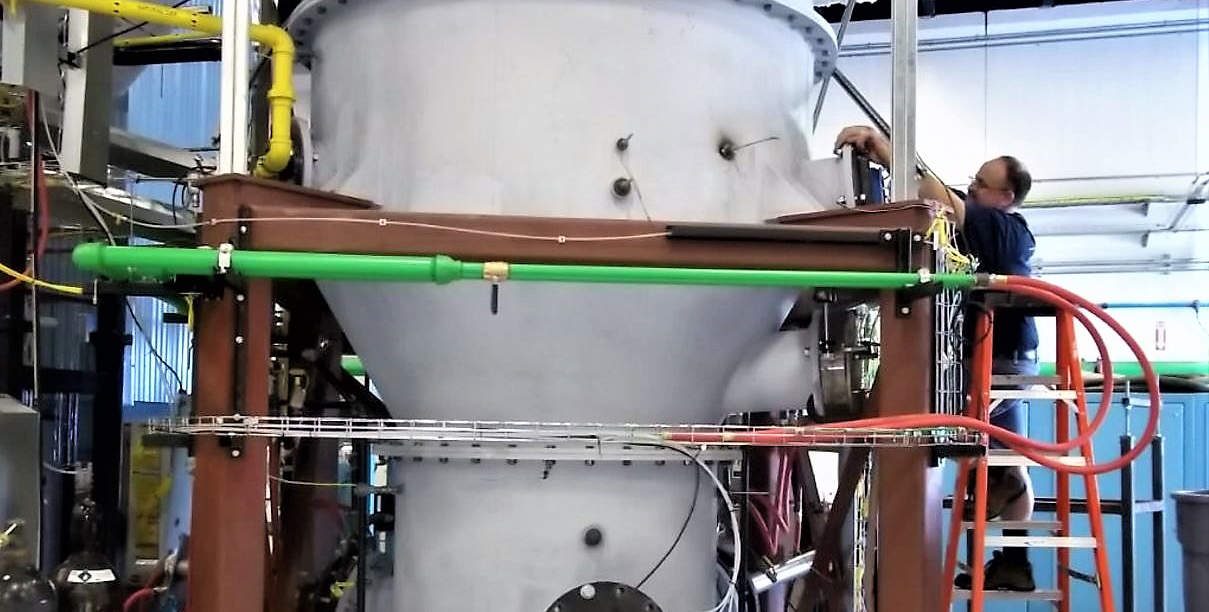

Plasma Plant Modules: 250 and 500 ton per day

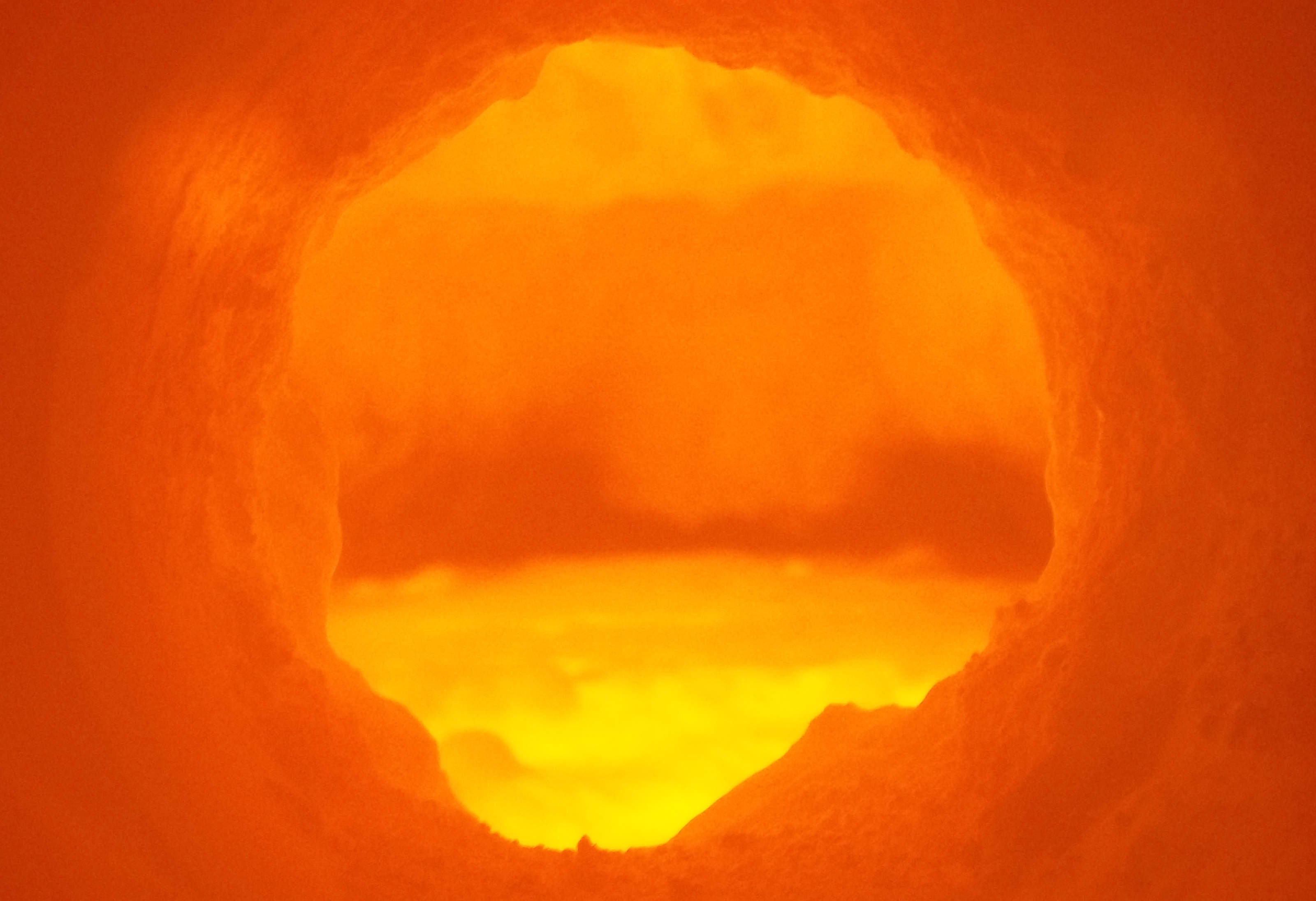

The proprietary H.E.A.T plasma assisted vitrification technology employs the power of plasma energy to accelerate material decomposition into gases, vitrified materials and metals to then be utilized for beneficial reuse purposes. Our series of plasma products innovatively utilizes latest generation plasma torches in combination with our proprietary induction furnace and chamber systems.

Features include:

- Scalable unit process capabilities ranging from 5 to 500 tpd of feedstock

- Operating temperatures greater than 5000°F with peak temperatures reaching 28000°F

- Intense levels of thermal energy and aggressive turbulence yield accelerated decomposition time

- Separation of organic and inorganic fractions including metals extraction

- Elimination of VOCs and other carcinogens

- Vitrification and encapsulation of toxic metals with amorphous material and made inert

- Molecular recycling of all feedstock resulting in beneficial reuse products

- Elimination or capping of contingent landfill economic and environmental liabilities

- Regenerating high value products such as energy for power generation and green hydrogen

Ultimately the H.E.A.T thermal conversion solution enables our customers to eliminate solid waste and the associated environmental risks by transforming these waste materials into beneficial reuse products, helping all in the pursuit of global environmental sustainability.

Products and Offerings

Plasma Plant

Design & Build

Core Plasma

Technology & Required

Products Supply

Efficient Gasification

Processes and

Systems

Reliable Power

Conversion

Processes

Production Processes

for Beneficial

Re-Use Byproducts

Sustainability & ESG Benefits

- Brings the circular economy to life through molecular recycling

- Eliminates the creation of chars or ash in the process

- Reduces the amount of emissions per unit of power generated

- Produces the maximum of reclaimed material per unit of feedstock

- Eliminates present and future environmental liabilities

- Delivers facilities requiring a minimum footprint